Reactivity Magnesium Oxide

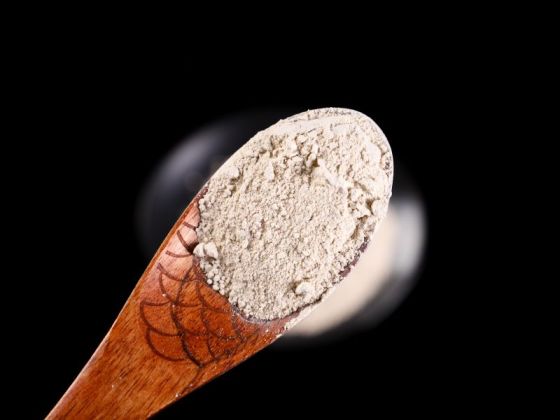

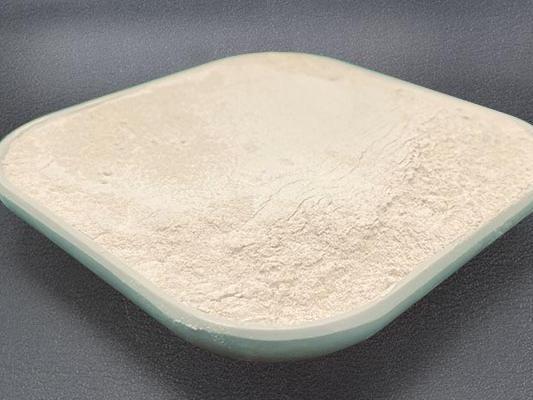

Caustic calcined magnesia (CCM) is a highly reactive form of magnesium oxide produced by calcining crude magnesite, brucite, or magnesium hydroxide extractedfrom brine at temperatures between 600°C - 1000°C. Msia Refractory Calcined Magnesite produces and commercializes a great varietyof caustic calcined magnesia products. CCM is mainly used in: Agricultural applications, Hydrometallurgical processes, Pulp and paper, Construction and Sorel cement, Chemicals and pharmaceuticals industry, Environmental applications, Glass industry.

- YKLX

- Liaoning,China

- as per the order's Qty

- 10000ton/month

- Information

Caustic calcined magnesia (CCM) is a highly reactive form of magnesium oxide produced by calcining crude magnesite, brucite, or magnesium hydroxide extractedfrom brine at temperatures between 600°C - 1000°C. Msia Refractory Calcined Magnesite produces and commercializes a great varietyof caustic calcined magnesia products. CCM is mainly used in: Agricultural applications, Hydrometallurgical processes, Pulp and paper, Construction and Sorel cement, Chemicals and pharmaceuticals industry, Environmental applications, Glass industry.

Magnesite (Magnesium Oxychloride) Flooring:

Magnesite flooring is not commonly used at the current time but was very popular for domestic applications in the period 1920 to 1940, and for Local Authority housing between 1945 and 1960. It is usually a reddish pink colour although some floors were coloured using pigments. It was commonly applied on top of concrete ground floor slabs. Magnesite flooring was made from a mixture of calcined magnesite and magnesium chloride solution with various fillers (e.g. wood flour, sawdust, asbestos). It was typically laid between 10 and 25mm thick, but two coat applications could be up to 50mm thick. Magnesite floorings are very vulnerable to dampness and if there is any doubt about moisture protection, it should be replaced. Chlorides may migrate from the magnesite into the concrete below and corrode any reinforcement or gas and water pipes. Most magnesite floors are now coming to the end of their life, only if they can be guaranteed to remain unaffected by moisture can they be used as a screed to receive other floorings, otherwise the flooring should be replaced.

Magnesium Oxide Wet Scrubbing System For Flue Gas Desulfurization

Reduced sulfur dioxide (SO2) emissions

Improved corrosion resistance

Reduced sorbent consumption

Wet scrubbers are used in utilities, paper mills, and chemical plants to remove sulfur dioxide (SO2) and other pollutants from gas streams. Undesirable pollutants are removed by contacting the gases with an aqueous solution or slurry containing a sorbent. Lime / limestone systems are most common for SO2 removal but magnesium oxide (MgO) slurry is sometimes used as an alternative.

After fly ash removal, the flue gas enters the scrubber (Figure 1) where it comes in contact with the MgO slurry. The SO2 is absorbed in the scrubber slurry and forms insoluble magnesium sulfite (MgSO3) as in the equation below.

MgO(s) + SO2(g) → MgSO3(s)

Application:

Construction: ·Industrial Flooring ·Ceramic tiles, boards & panels ·Abrasives

Industrial: ·Hydrometallurgy ·Pulp & Paper

Specialties: ·Glass making ·Friction materials

Agri-business: ·Animal Nutrition ·Fertilizers ·Agriculture

Enviromental: ·Soil decontamination ·Waste neutralization ·Water treatment ·Flue gas treatment

| Industrial grade | |||||||

| SPECIFICATIONS | MgO %min | SiO2 %max | CaO2 %max | L.O.I %max | Al2O3 %max | Fe2O3 %max | Size |

| MGO-85CCM | 85 | 7 | 3 | 5 | 1 | 1 | 80-200mesh |

| MGO-88CCM | 88 | 6 | 2 | 4 | 1 | 1 | 80-200mesh |

| MGO-90CCM | 90 | 5 | 2 | 3 | 1 | 1 | 80-200mesh |

| MGO-92CCM | 92 | 4 | 2 | 2.5 | 1 | 1 | 80-200mesh |

| Agricultural grade | |||||||

| SPECIFICATIONS | MgO %min | SiO2 %max | CaO2 %max | L.O.I %max | Al2O3 %max | Fe2O3 %max | Size |

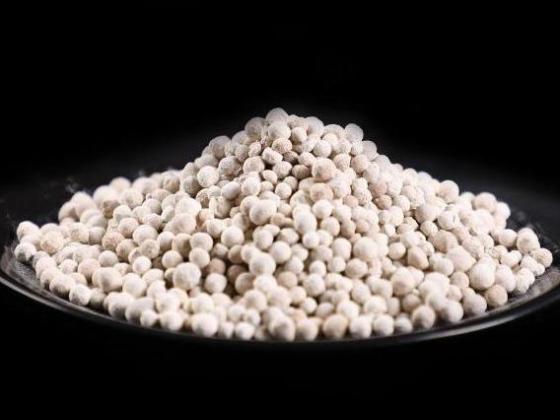

| MGO-65CCM | 65 | 15 | 5 | 24 | 1 | 1 | 2-5mm |

| MGO-65CCM | 65 | 15 | 5 | 15 | 1 | 1 | 80-200mesh |

| MGO-80CCM | 80 | 9 | 4 | 8 | 1 | 1 | 80-200mesh |

| MGO-85CCM | 85 | 9 | 3 | 5 | 1 | 1 | 80-200mesh |

| MGO-90CCM | 90 | 5 | 2 | 3.5 | 1 | 1 | 80-200mesh |

| Feed grade | |||||||

| SPECIFICATIONS | MgO %min | Mg %min | SiO2 %max | CaO2 %max | L.O.I %max | Al2O3 %max | Size |

| MGO-84CCM | 84 | 50 | 7 | 3 | 7 | 1 | 80-200mesh |

| MGO-87CCM | 87 | 52 | 6 | 3 | 6 | 1 | 80-200mesh |

| MGO-90CCM | 90 | 54 | 4.5 | 2 | 4.8 | 1 | 80-200mesh |

| MGO-92CCM | 92 | 55 | 3.5 | 2 | 4 | 1 | 80-200mesh |